Development Plan / Master Plan

We can help you develop your plant by producing a technical development plan in a

structured manner. This type of plan can go by a number of different names, for example Master Plan, Long-term Development Plan (LDP) or Business Continuity Plan (BCP). Here we have chosen to refer to it as a Master Plan.

A Master Plan can be used to create supporting documentation for the development of the plant with reduced production costs as a goal, map investment requirements, identify technical business risks or create a picture of the efficiency improvement potential at the production plant. A Master Plan functions as decision-support documentation for overall structural decisions that impact the total production capacity in a business.

The plan can also advantageously be used as an overall approach to energy efficiency

measures and as a useful tool in the work involving the identification of fire and explosion risks, for example in connection with a future expansion of the plant. Being able to achieve a holistic view of the energy flow at the entire operating site provides opportunities for development and taking your work to the next level, often with savings of 20-30% as a result.

The production of a Master Plan occurs through a work process that commences with the definition of applicable planning assumptions. This process involves the development of planning and design parameters that represent conditions for the plan, along with the definition of the capacity- and production-related technological needs that exist or will arise. The next step involves mapping of the current technological situation in the business, followed by a cost analysis of the current production process.

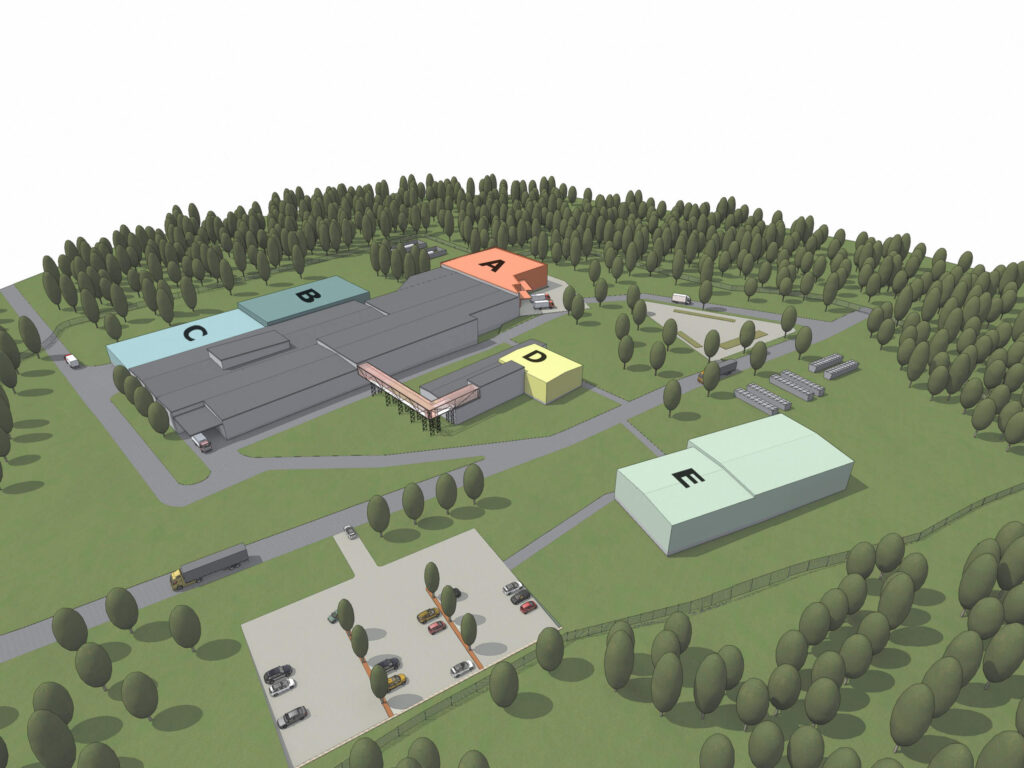

Based on this analysis of the current situation and the anticipated future needs, an overall plan is prepared for the development of the plant, including systems and building facilities. The plan is also illustrated to provide the best possible overview.

It is common for a Master Plan to include an analysis of the null alternative. The null

alternative describes what will happen if no development takes place, i.e. if no action is taken. This part of the plan describes the need for reinvestments.

A close dialogue takes place between Qestio and the client throughout the entire process, to ensure that all relevant conditions and needs are taken into account. The work is summarised in a report that describes the different phases of the development plan, including an overall description of changes, investment needs (CAPEX), impact on overhead costs (OPEX) and consequences, as well as the division of the Master Plan into different phases.

Are you faced with the need to describe the development of your production facilities? Would you like to know more about how the team at Qestio can assist you with this work? Contact us!